ABOUT

Deyang Litong Printing Machinery Co., Ltd., as a professional cutting production line manufacturer, produces and sells post-press Cutting Production Line components, including Paper Cutter, Pile Unloader, Pile Loader, Pile Lifter, Stack Jogger, Pile Turner, Air Table and other related products. Litong’s purchasing, production, quality and sales management are fully established on advanced internet based ERP system. Company obtains the ISO9001 quality, ISO14001 environment and OHSAS18001 health and safety management certificates. The performance of all products has reached the international advanced level and reflects the top quality of the Chinese post-press equipments.

Following the path of innovation, with strong research and development capability, Litong owns more than 60 patents and possesses full intellectual property rights of all products. Litong Paper Cutter fulfills the highest European CE safety standard and is certificated by TÜV Rheinland. All series of Paper Cutter features high cutting precision, high speed, low energy consumption, especially, the patented intelligent energy saving techonlogy can achieve 75% enenrgy saving compared to traditional paper cutter. Litong Pile Unloader, with our latest clamping unloading technology, can provide ultra-high unloading precision(±1mm) for direct printing and pushes the design and manufacture of unloading system to a new level. Litong Pile Loader, using its revolutionary paper separating system to overcome worldwide difficulty of loading thin paper, can be implemented to both printing and packaging areas and improve productivity significantly. Litong Stack Jogger is equipped the world’s first double-size stepless inclination jogging system, which conquers the world-class problem of jogging thin paper. Litong Pile Turner owns unique patented curve-guided turning system, it greatly improves turning efficiency and reduces energy consumption. Litong Air Table has world’s first automatic air valve and ultra-thin chromed steel working table, which can automatically detect materials and open the air cushion only under the material.

By insisting on the motto “innovation and commitment”, Litong strives to provide our customers outstanding products and perfect services.

HISTORY

1958

Birth of Litong’s predecessor company

1980

Success of first self-developed Paper Cutter

1985

Developed the first digital display Paper Cutter in China

1988

Developed the first hydraulic dual-digital displays Paper Cutter in China

1992

Birth of the “LITONG” brand

Developed the first program-control Paper Cutter in China

1993

Founded the Litong Shenzhen branch

1994

Developed the world’s first dual-rail guided backgauging Paper Cutter

1996

Won the “China Top Brand”

1999

Won the “National High-tech Enterprise”

2000

First enterprise to employ the EU safety standard in China

2003

First Chinese enterprise owned the intellectual property rights of Paper Cutter

2004

Won the “Sichuan Province Famous Trademark”

2005

Foundation of Deyang Litong Company

2008

Won the “Top Ten National Manufacturer”

2009

Won the “Sichuan Province Top Brand”

2011

Developed the world’s first high efficient 25% energy saving Paper Cutter

2012

Developed ±2mm unloading precision Pile Unloader

2013

Won the “Quality brand of China Machinery Industry”

2014

Developed the world’s first 16mm ultra-thin automatic Air Table

2015

Developed the world’s first Pile Loader with bionic loading system for normal paper

Developed the world’s first stepless inclination Stack Jogger

2016

Developed the world’s first curve guided high speed Pile Turner

Developed the world’s intelligent 75% energy saving Paper Cutter

Developed the world’s wireless controlled Paper Cutter

2017

Developed the world’s first Pile Loader with bionic paper separating system for thin paper loading

Developed ±1mm high unloading precision Pile Unloader with clamping unloading technology for thin paper

CERTIFICATES

ISO 9001 : 2008

Quality Management

ISO 14001 : 2004

Environment Management

ISO 18001 : 2007

Health and Safety Management

China

Top Brand

National

High-Tech Enterprise

CE Safety Products

Certified by TÜV Rheinland

Chinese Machinery

Premium Brand

China Green

Equipment Award

Sichuan Province

Famous Trademark

Enterprise of Good

Creditworthiness Certificate

China High-tech

Technical Center

Adopting International Standard

Products Certificate

TECHNOLOGIES

FULL RANGE OF PRODUCTS

MORE THAN 60 PATENTS

Paper Cuter

Intelligent Energy Saving System

Paper Cutter

Smart-Touch HMI

Paper Cutter

Remote Service System

Paper Cutter

Wireless Control System

Paper Cutter

Dual Linear Guide Cutting System

Paper Cutter

Dual-rail Guided Backgauging System

Paper Cutter

Maintenance Free Integral Backgauge

Paper Cutter

Integral Casting Frame

Paper Cutter

Balanced Weight Clamping System

Paper Cutter

Infrared Safety Light Barriers

Paper Cutter

Dual-function Hydraulic Cylinder

Paper Cutter

Metallic friction clutch disc

Paper Cutter

Hydraulic Clutch Cutting System

Paper Cutter

Soft Clamping Function

Paper Cutter

Clamp Height Control Function

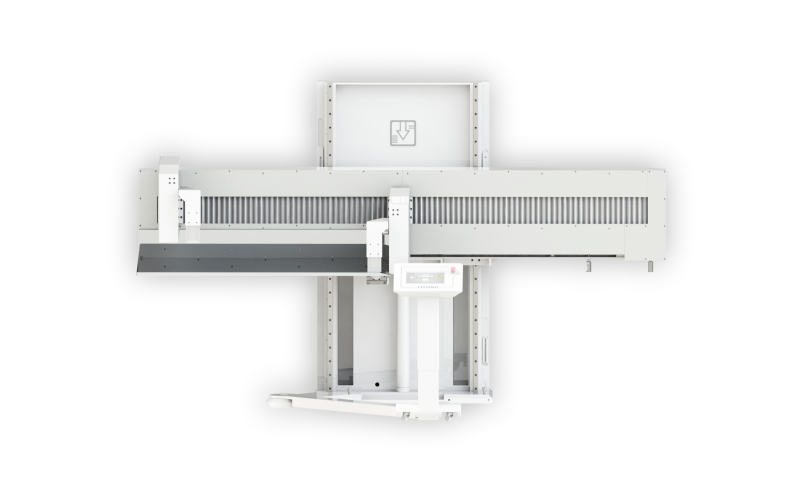

Pile Unloader

Clamp Unloading System

Pile Unloader

Automatic Paper Size Recognition

Pile Unloader

Dual-auxiliary Aligning Arms

Pile Unloader

Integral Casting Frame and Beam

Pile Unloader

Movable Control Desk

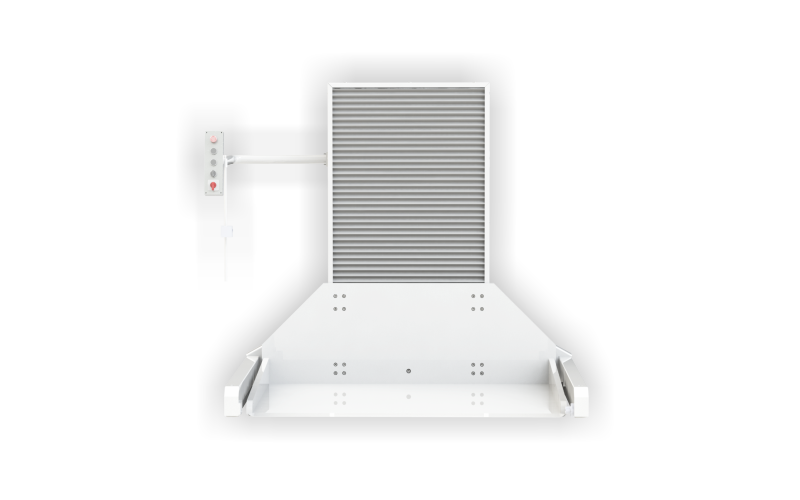

Pile Loader

Bionic Loading Technology

Pile Loader

Thin Paper Separation System

Pile Loader

Plow Type Loading Table

Pile Loader

Integral Casting Frame and Beam

Pile Lifter

Integral Casting Body

Stack Jogger

Stepless Inclination System

Stack Jogger

Hydraulic Inclination System

Stack Jogger

Integral Casting Body and Frame

Pile Turner

Curve Guided Self Weight Turning

Pile Turner

Integral Casting Body

Air Table

Chromed Steel Working Table

Air Table

Automatic Micro-pore Air Cushion

Air Table

Integral Plastic-free Air Cushion

All patents are independent intellectual property of LITONG. For patents’ information, please refer to the State Intellectual Property Office of P.R.C.

MANUFACTURE

Plant

Total area of 50,000 square meters

Modern full enclosed plant by US BATLER

More than 50% area is covered by green

Processing

High-tech processing equipment

LITONG-designed machining center

German and US CNC machining center

Management

Strict manufacturing control

Lean production system

Quality management system

Production

Advanced assembly production line

Clean hydraulic, electrical assembly shop

Modern surface processing and painting line

SUPPLIERS